We are discovering that Match-IT has some features that are not always translatable or present in other systems. When migrating to an alternative system you can use the list below as a guide for potential problems.

Note than in Match-IT a “method” is a sequence of “steps” with each step detailing the materials/parts and resources needed to complete the step. Methods can also have sub-contract steps. Other systems will use terms like “bill of materials”, “assets” “routing” and “work centres”.

Weight – Quantities can be specified as a weight, for example when booking-in Match-IT will calculate the number of items/bars/sheets.

Generic Units – The ability to define units and their conversions for use in all Match-IT contexts.

Unit Abstraction – For example specifying the number of sheets needed in square metres. This can be useful in methods if you need a total length/area regardless of item size. Another example would be booking-in.

Tessellation – Match-IT knows how to cut up 1D and 2D parts to calculate expected returns. Relatedly Match-IT knows not to tessellate fluids.

Part Profiles – User definable item/bar/sheet profiles. For example a 1D hexagonal bar.

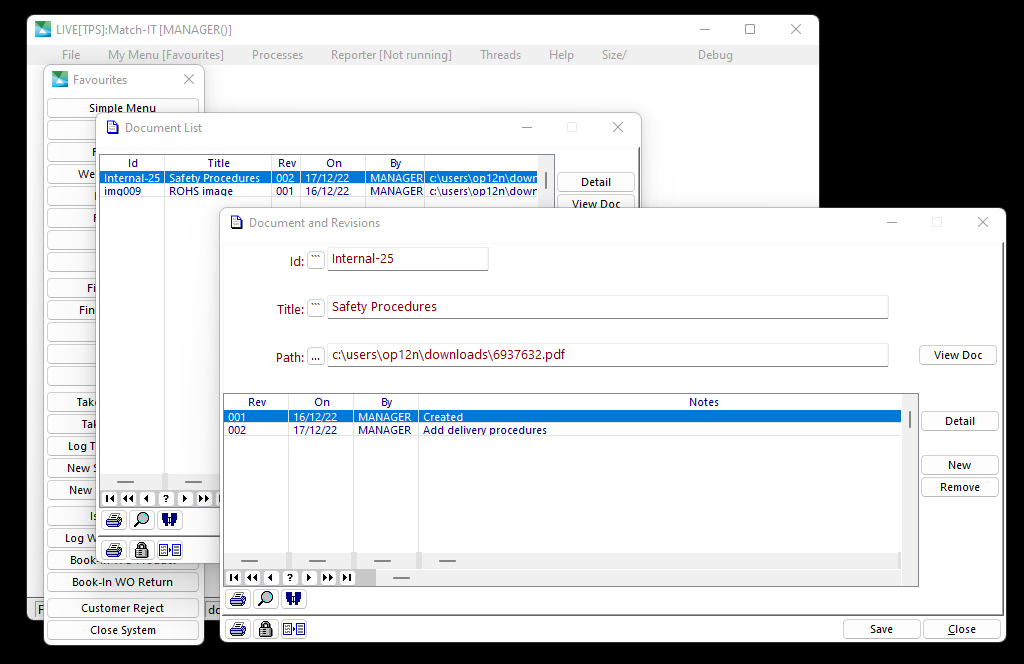

Qualifiers – Typed user extensions to the database. For example to attach PDFs and first-article inspections to part records etc. Qualifiers can be used when printing documents to extend the repertoire of available data.

Step-Level Parts – Every step in a method has a corresponding part record facilitating partially complete or failed WOs being booked in at the step level. The scheduler will use these batches as needed to partially satisfy a method schedule.

Checklists – User definable options that must be completed before document approval and configurable for each document type: SO, PO, SCPO, WO, Quote etc.

Configurable Menu Structure – At a system and user level.

Event Diary – A daily to-do list specialised to each user.

Multiple Outputs – Something that is made as a side-effect of making something else. Match-IT will schedule the containing part if it has a demand for the side-effect.

Merging – A post-schedule iterative process whereby WOs and POs are combined based on date constraints to minimise setup costs. This is a powerful feature that is surprisingly absent in many other systems.

Contextual Configuration – For example customer/supplier based paperwork designs (which facilitates running more then one company within Match-IT).

Drill Through UI – From any field the user can navigate to all related records.

Scripting – Match-IT uses Lua as a scripting language. Scripts can access all areas of Match-IT.

Finite Capacity Scheduling – Using one minute granularity.

Partial Rescheduling – Allowing a sales line and any related demands to be rescheduled in a self-contained bubble.

Field Level Security – User groups define access and security rules from processes and files to individual fields.

Aerospace Level Traceability – Using a tree-based UI with various detail options.

Resource Groups – Whereby the scheduler will evaluate ‘the best’ option from a group of alternative resources.

Services – Parts which are invoiced but not delivered.

Consumables – Parts which can be used indefinitely once booked in.

Alternative Parts – Allowing the scheduler to substitute one part for another to keep schedules on time.

Flexible Scheduling Strategies – Cheapest, Quickest etc.

Scheduling Options – Notably to not mix batches in an Aerospace context.

Auditing – Every user action is logged for the last 90 days (configurable) allowing you to answer ‘who changed this to that’ etc.

Method Expressions – Allowing methods to be defined for non-linear part associations.

Disassembly Methods – Allowing returns to be dismantled and re-engineered.

Price Breaks – Prices, costs and lead times etc. are contingent on customer/supplier and quantity.

Customer/Supplier Specific Paperwork – Allowing you to run multiple companies with a different ‘look’ – all from a single Match-IT instance.

Multiple Installations – Your licence covers as many installations as you like which is another way to run multiple companies.

Historical Reprinting – Enabling you to reprint documents the way they were when initially printed.

Assembly Library – Method fragments that can be referenced from or dragged into a method.