Top Level Method

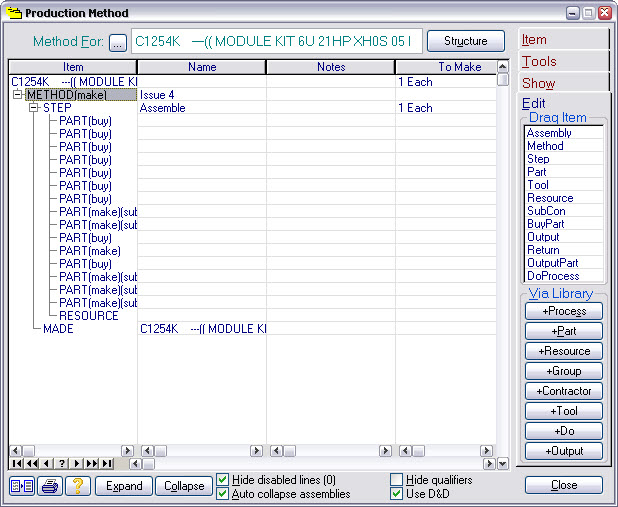

The first time you open a window, Match-IT opens it at its smallest size in the middle of the desktop. This is often not the best size or place, as in this case:

You can adjust the size of the window and the width of the columns by dragging in the usual Windows™ way.

Match-IT will remember your settings, including the column widths.

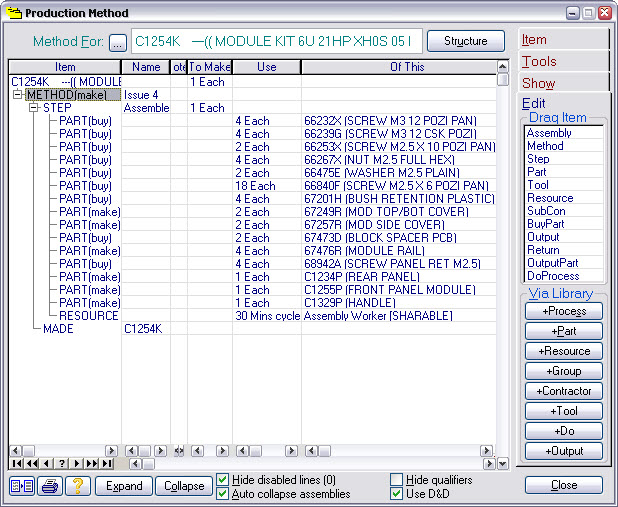

Re-size the window and the columns until it looks more like this:

Our C1254K example is an assembled product, made up from a mixture of bought-in parts and manufactured parts. The method we’re looking at here is for the final assembly. It consists of a list of 15 parts and sub-assemblies, and one resource (assembly worker) to put it all together.

Each PART record specifies what the part is, and how many are required to make one C1254K. For example, the method above specifies that four 66232X screws are required. The scheduler uses this information to calculate costs and to allocate stock.

The RESOURCE record specifies the resource to be used and how much time is required to assemble one C1254K (the cycle time) and how much time is required to prepare to make any number (the setup time). In the method above, the assembly worker requires 5 minutes to get ready, and 30 minutes to assemble each C1254K. This information is used to estimate costs and to allocate time.

These methods can be edited very easily, for example, by double clicking on a column entry to change it, or by dragging to move a record up or down the method. There are also a number of tools available that allow you to construct these methods from boilerplate templates. We won’t go into that here.

Match-IT does not differentiate between a PART that is bought-in from one that is made. This means you can have assemblies within sub-assemblies to any depth you like, with bought-in parts mixed in at any level. We’ll briefly look at one bought-in part and one sub-assembly.

Highlight the 66232X part. This is a bought-in part, so pressing Suppliers on the Show tab will bring up the list of suppliers and prices for it, as shown below.