The Stock Allocation Model

Stock allocation is totally automatic. Under normal circumstances the system will find appropriate stock and automatically allocate it to works orders and sales orders as necessary. This allocation is done as soon as the sales order is approved. The allocation may be from physical stock or WIP or planned purchases or planned works orders. The allocated stock is also automatically issued to a job when you approve the job and also automatically taken away when you approve a dispatch. The stock control system will never over allocate stock and it will automatically detect shortages. Shortages will trigger appropriate purchase order and works order suggestions to cover them. Provided you keep the system up to date, you will never run out of stock and you will never buy or make more than you need to cover your commitments.

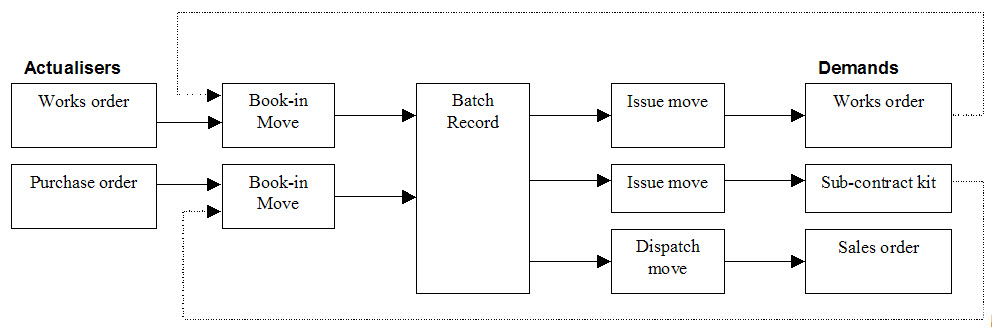

The key to understanding how this is achieved is by understanding the importance of stock moves. Every stock transaction is modelled by a movement record attached to a batch record. These movement records either increase the stock level or decrease it or note some other condition (e.g. a write-off). But also, crucially, they provide the connection between a demand and an actualiser. A demand is something that requires the use of stock, be it a sales order or kit for a works order or just a minimum stock requirement. An actualiser is something that satisfies the demand by creating stock, e.g. a purchase order for bought things or a works order for made things. The planning system examines the demands, calculates stock shortages, then makes purchase order and works order suggestions to fulfil the shortages.

The ‘glue’ for all this are the batch records and their associated movement records. The diagram below shows a simplified view of how they are connected:

By following these connections you can find everything that is related to anything, either forwards or backwards. For example, to find out where a purchased item went, just follow the book-in move from the purchase into its batches, then follow the issue records from there to the demands. If that is a works order, just keep going by following its book-in moves to the batches created from that and on into the issues from there, and so on until you arrive at the sales order. The trace forward facility does this for you automatically. Similarly, to find out how a sales order is being satisfied, follow its dispatch moves back to the batch, and then out through its book-in moves to the source of the batch. If that’s a works order, just continue through the works order kit until you arrive at a purchase order. The trace backward facility does this for you automatically.