Resource record

A resource record specifies a person or a machine that is required to perform some operation and how much time is required. The resource can be specified explicitly or it can be chosen from a group of similar resources. Like PART records, you can specify choices. Choices are particularly useful for resources as it helps to prevent bottlenecks. If a particular resource is busy when there are choices, the planning system will just look for one that is not busy. If there are no choices available, the job will be delayed until a suitable resource becomes available.

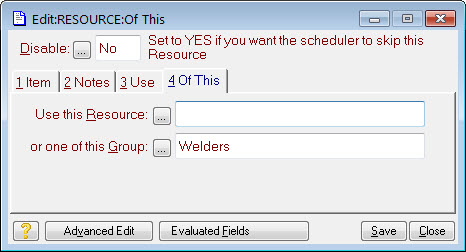

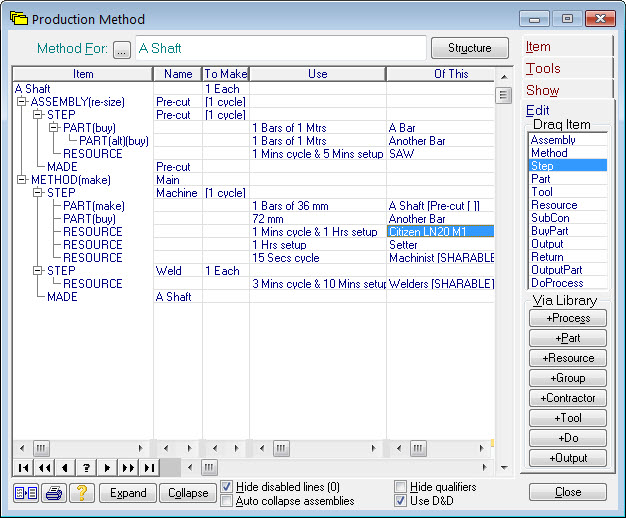

Using resource groups is also useful to model skills. E.g. in a method requiring a welding skill, rather than specify particular people with that skill, instead define a group called ‘welders’ and put the people with that skill in the group. Then in the method just say you need a ‘welder’:

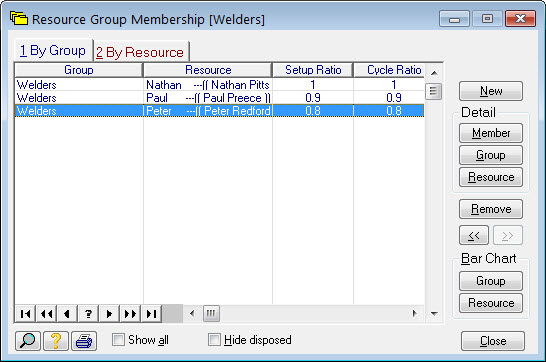

There are two main benefits to this: 1) you only have to change one thing as you hire and fire welders – the group membership; 2) you can specify relative capabilities so that more capable people are used in preference to less capable ones:

The setup and cycle ‘ratio’ in the above example shows the relative capabilities of the members of our welders group. A value of 1 is the benchmark, values less than 1 indicate less capability and values more than 1 indicate more capability.

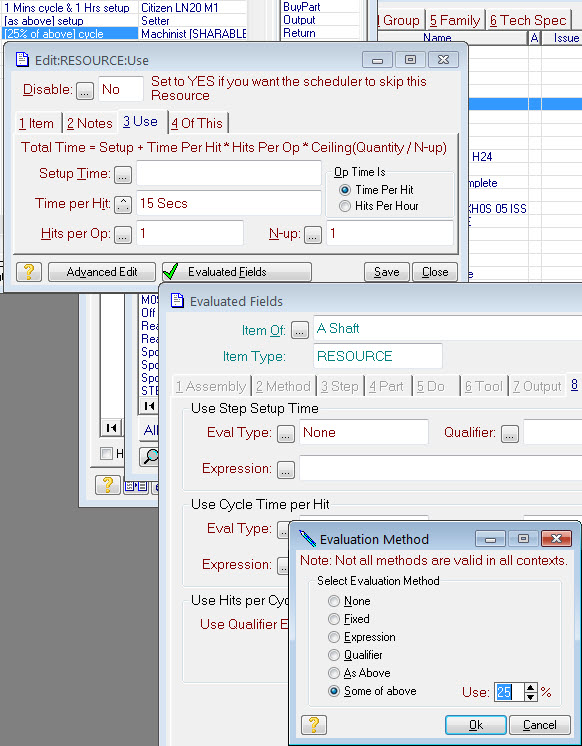

There are two types of time that can be specified for a resource: setup time and cycle time. The setup time is fixed, it represents preparation time, the same amount is required no matter how many things you are going to make. The cycle time usually represents how much time is required to make ‘one’ of something. This time is scaled up by the planning system to reflect how many are actually going to be made. Like PART quantities there are a number of aspects of resource time:

The form above shows the various factors and is reached by selecting advanced edit on a resource record. Right-click on a field to learn more about it.

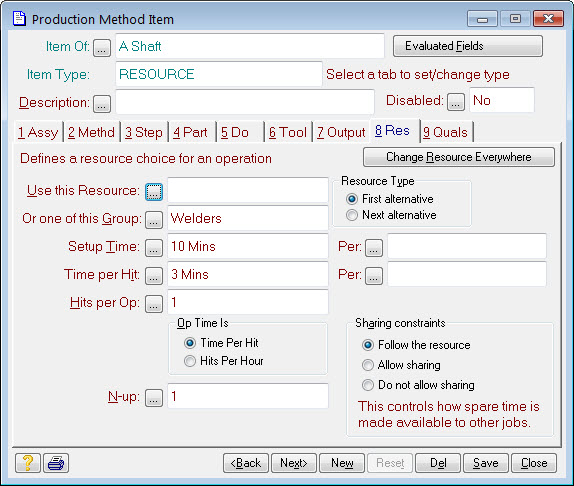

As well as resources choices, an operation may also require multiple resources to perform its operation:

The machine step in the above example has a requirement for three resources: the Citizen LN20 M1 AND a Setter AND a Machinist. Notice the Setter has no cycle time and the Machinist has no setup time. This means you need a Setter only for setup and he’s released once the setup is complete and the Machinist is not required until the machine has been set. Also, notice the cycle time for the Machinist (15 seconds) is less than that of the Citizen LN20 (1 minute). This means the Machinist is not fully occupied running the Citizen and because the Machinist is ‘sharable’, he is allowed to be allocated to other jobs to use up any spare time.

Generally, machines are not sharable and people are. Sharable means the resource is allowed to be allocated to more than one job at a time.

When using multiple resources in a step, as in the Machine example above, you can alternatively specify the times relative to the first resource on the step. This means you only have to edit one record should you decide to update the times for the step. This is particularly useful when the step is defined as a ‘boiler-plate’ in the process library. To specify times as relative, use the Evaluated Fields tool and select the As Above or Some of Above options as the Eval Type, as illustrated below: