Quantities (Use column)

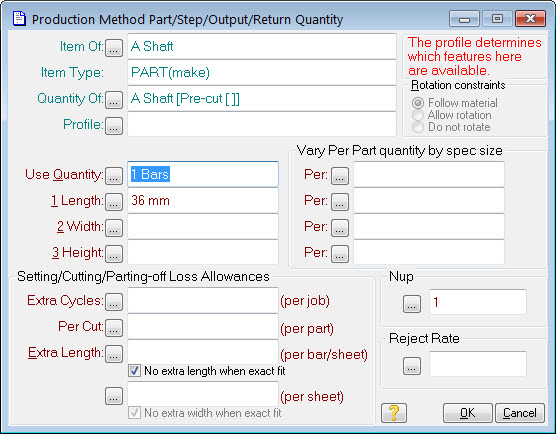

The quantity of a PART specifies how much of the material is required to make the unit quantity of the product. The unit quantity is shown in the To Make column. When dimensioned material is involved (e.g. bars, rods, extrusions, sheets, plates, etc.) there are a number of ‘loss’ allowances that can be specified. The form below shows the various aspects of a quantity. This form is reached by selecting advanced edit then more...

Right-click in a field to get an explanation of that field.

The planning system is aware of dimensions and takes yields into consideration when allocating part of a ‘thing’. Depending on how you specify the quantity you want, the yield calculations will be ‘strict’ or ‘lose’. A strict calculation takes all dimensions into account and will ensure only pieces that are big enough are allocated. A lose calculation doesn’t care about physical sizes so long as the quantities ‘add-up’, e.g. 20mm + 30mm is good enough to satisfy a requirement for 50mm when being lose but not when being strict.

If the quantity you require is purely specified as a length, e.g. 36mm, then you are being ‘lose’ and saying “I don’t care how the big the pieces are so long as they add up to 36mm”.

If you want the quantity as a single piece of a required length then you must specify it as “1 bars of 36mm”.