Method

A Method record marks the beginning and end of a production method. There may be more than one method record, in which case you are defining alternative ways to make something. In this case the planning system uses the first (enabled) method it comes across (starting from the top) and the rest are ignored.

There are several types of method:

Make

A make method defines a production method to turn raw materials into products. This is the usual case, see example above.

Dispatch

A dispatch method defines a method that is used to prepare stock for dispatch, such as re-packaging. These are optional and if present cause a works order to be produced for every dispatch. They can only consist of a single STEP and that step must have a SELF part in it. They are useful to capture time and materials used for dispatching where the product is usually made for stock and kept on your shelves until needed. If you make and dispatch to order, it's usually more convenient to add a STEP in the make method.

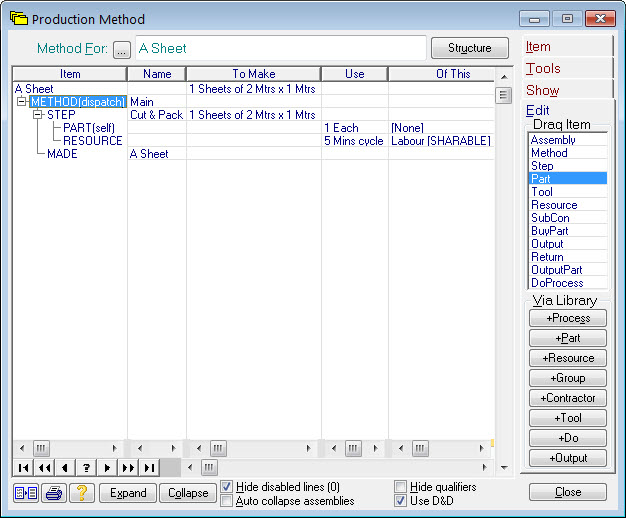

Here is an example of a dispatch method that cuts and packs a part of A Sheet we created earlier:

Notice the PART(self). This means, “I want whatever size the customer asked for in the order”. A self part is a part record with no material (i.e. Of This is blank). If you do a test for various sizes you’ll see that the planning system calculates the yield from your stock sheets and allocates an appropriate number to be cut as required.

Also notice, this dispatch method is attached to a bought material. That’s fine, it just means you are prepared to sell your raw materials.

Goods-In

A goods-in method defines a method that is used prepare stock for the shelf that has been received from suppliers. This is useful to model significant processes, such as un-packing and inspecting. These are optional and if present cause a works order to be produced for every delivery expected from your suppliers. They can only consist of a single STEP and that step must have a SELF part in it.

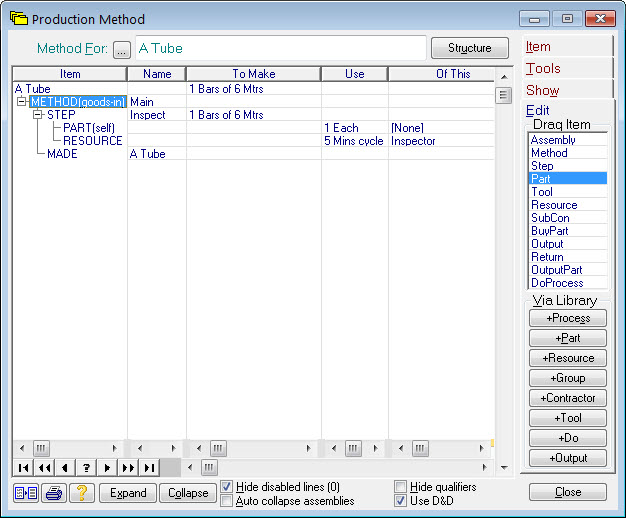

Here is an example of a goods-in method that inspects A Tube:

In this case the SELF part means, “use whatever was delivered”.

Dis-assembly

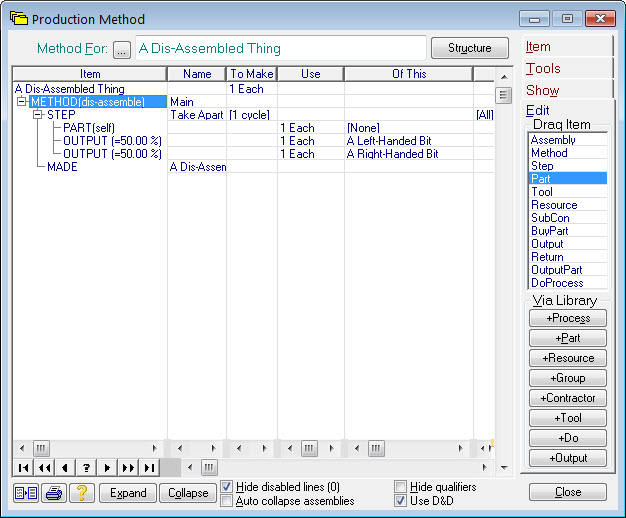

A dis-assembly method defines a method that is used to take a bought assembly to pieces. This is useful if you want to use components of the bought thing in your products and this is the only way you can get the components (think of the bought thing as a ‘kit’ of useful parts). Here is an example that extracts two parts from a bought assembly:

Here the SELF part means “take whatever we bought”. The two output records define what is being extracted and what they’re worth (as a percentage of the cost of buying the whole thing). Any method that requires A Left-Handed Bit will cause the assembly to be bought (via a Purchase Order), then taken apart (via a Works Order), then the part extracted is allocated.

End

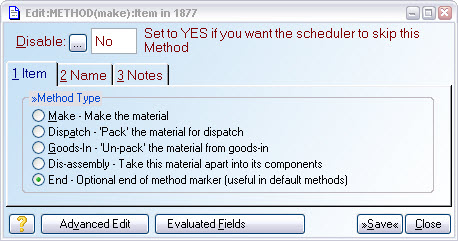

An end record marks the end of a production method. They can be left out if the context is un-ambiguous, buts its safer to always use them, especially when you are using LIKE processes. To add an end record, drag a Method record onto the end of the method, double-click on it to bring up its properties, and select the End radio option. It should look like this:

It is particularly important to use a an explicit end method record when defining default methods. To not do so will invalidate the default method and it will not be used.