Check delivery date

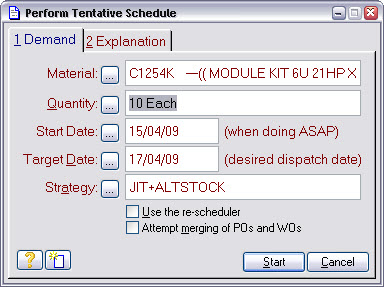

A confirmation form like the one here will be shown to you:

The Target Date: shown will be the required delivery date after the carriage delays have been removed. These are defined by the carriage rule associated with the order. A default value for this was set automatically when the order was raised.

The Strategy: field shows the scheduling options that will be used. JIT is Just In Time; this means the scheduler will work back from the target date to determine when things must be done to meet that date. If in doing this it works back past today, it means the date cannot be met. When this happens the scheduler will abandon the JIT schedule and instead perform an ASAP one. ASAP is As Soon As Possible; in this mode the scheduler works forwards from today to determine when things will finish. A JIT schedule tells you when you must start to achieve a date, while an ASAP schedule tells you when you will finish if you start today.

The Match-IT scheduler performs simultaneous materials and resource planning (MRP and MRPII). It takes your capacity and stock position into account as well as work in progress and planned work. Match-IT uses a finite capacity scheduling system. It calculates how much time is required to do a job and then looks for that amount of free time on the machines needed. This means Match-IT will not allow you to become overloaded, instead your planned delivery dates will move out.

Leave the strategy as JIT and press Start to start the tentative schedule.

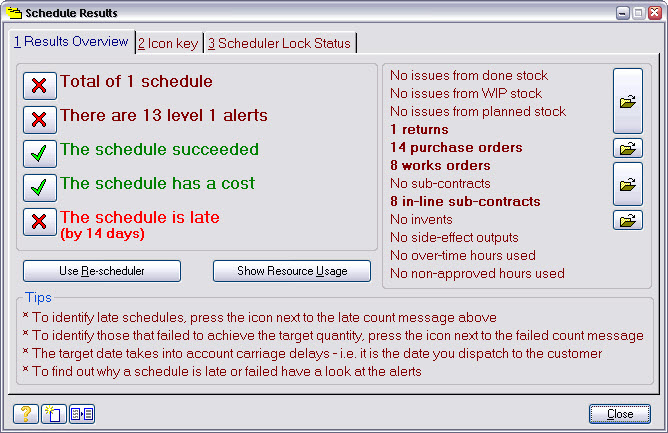

After some activity a form like this will be shown:

If you followed the suggestion in part 1 of the tour, to set a delivery date of 7 days time, you should see that the date cannot be met, as shown above.

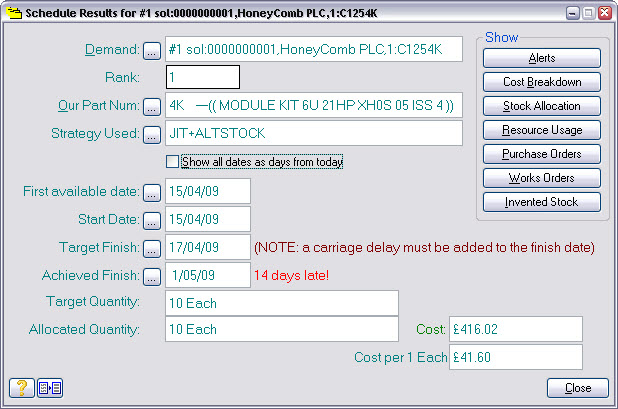

Pressing the ![]() against the Total of 1 schedule line will show you a summary of the schedule results, like this:

against the Total of 1 schedule line will show you a summary of the schedule results, like this:

Notice the Achieved Finshed field is showing the date that can actually be achieved.

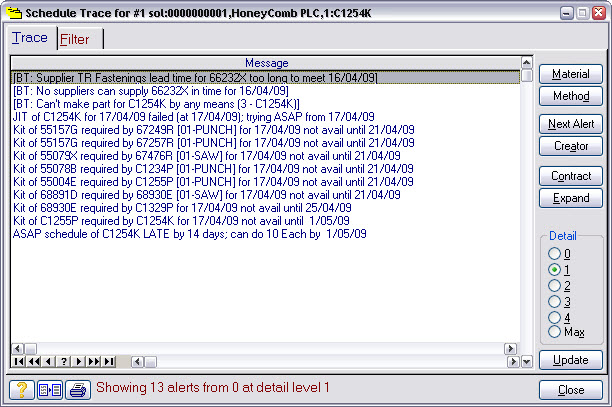

We can get more detail on why it is late by pressing the Alerts button:

In this case we can see from the Trace that a bought part is required and it cannot be supplied in time from TR Fastenings.

This makes the scheduler abandon the JIT option and start again using ASAP.

Note the date that can be achieved and press Close twice to get back to our order line.

The tentative schedule has calculated the date the goods will be ready for dispatch, you’ll need to make an allowance for the time taken to actually deliver them when setting the delivery date in the order.

Modify the To Deliver On: date to that you noted from the What if schedule? making due allowance for the carriage delay. Typically, you would need to confirm such a date change with your customer before committing to it.

We’re done checking the delivery date. You now know the date you are offering is achievable. The scheduler has taken everything it knows about into consideration when calculating an achievable delivery date. This includes:

•The materials and quantities needed for the job.

•The machines, tools, gauges and people needed.

•The amount of time needed.

•Your free stock position.

•Your expected supplier deliveries.

•Your suppliers’ lead-times.

•Your capacity on a day-by-day basis.

•Your current shop-floor loading.

•Your projected finish dates for work in progress

So if you keep Match-IT up to date on what’s happening, it can give you realistic delivery date predictions right at the very beginning of the job. This means you know very early if you are likely to encounter delivery problems and have enough time to do something about it!

We’ll now move on to the next stage in the approval process - the contract review. If you don’t run an ISO 9000 (or equivalent) quality system, you’ll probably set-up Match-IT so that you don’t need to do this. We’ll proceed on the basis that you do a contract review.

Press Close twice to get back to the orders awaiting approval list.

A typical quality system will stipulate that you perform a number of checks when you receive a new order. You can set-up Match-IT to remind you to do these checks and record the fact that you’ve done them, and who did them and when. Pressing the Check List button on the Sales Orders Awaiting Approval list will present a simple example.